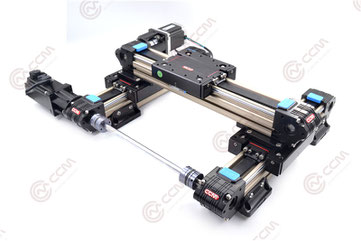

CCM W60-35 linear module

Regardless of your application, when considering the options among pre-assembled linear systems, start with the four primary application parameters—stroke, load, speed, and precision. Once the magnitude and importance of these criteria are determined, other parameters, such as noise, rigidity, and environmental factors, can help narrow the field and make final sizing and selection less time-consuming.

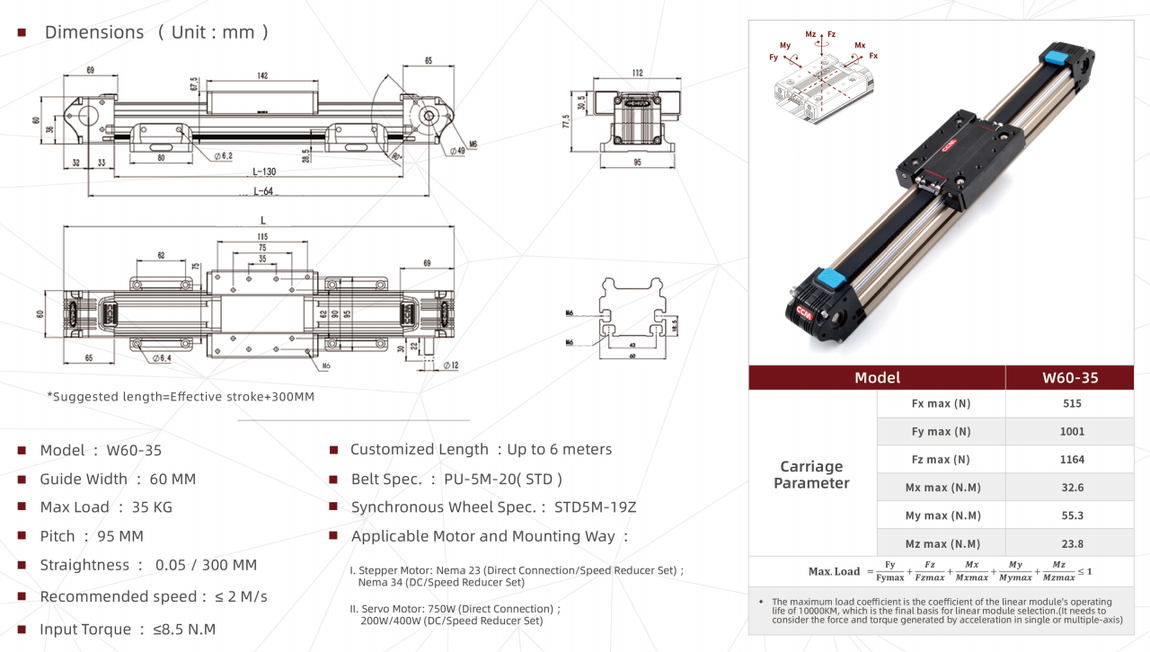

| Model: | W60-35 |

| Guide Width: | 60MM |

| Max Load: | 35KG |

| Pitch: | 95MM |

| Straightness: | 0.05/300MM |

| Recommended speed: | ≤2M/S |

| Input Toque: | ≤8.5N.M |

| Customized Length: | Up to 6 Meters |

Features

1) high accuracy

2) customised length up to 6 meters

3) anti-corrosion

4) maintenance-free

5) noiseless

6) low vibration

7) high reliability

8) high durability

9) flexible add-ons

Applications

Robotic arms

3D printer machines

CNC router machines

Pick and place machines

Glue dispenser

Painting machines

Packing machines

Coding machines

Gantry Robot

Laser engraving and cutting machines

......

How to order

1) Share your idea with us.

2) Provide us with weight of the load and stroke length for each axis, together with travel speed and structure.

3) Estimate costs/ quotation.

4) Put your order to production after payment.

5) Arrange the shipping for you.

6) Comment on the products and service so we can do better.

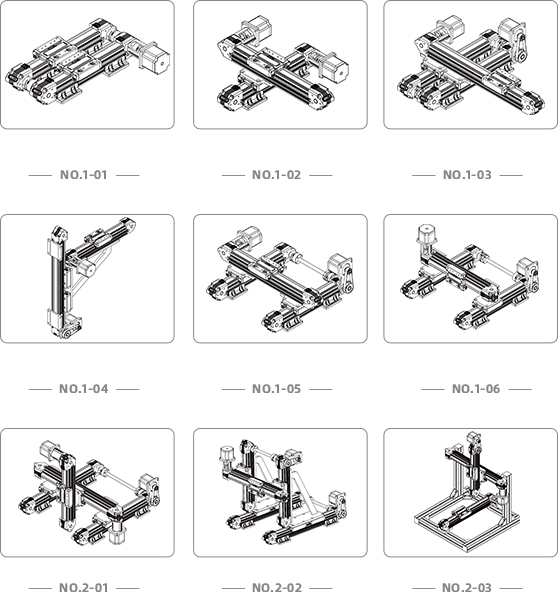

We offer motorized stages that can be assembled into many different configurations; for example, XY stages, XYZ stages .

We list a few common XY stage combinations here, but you can select your own combination of family, travel and lead screw pitch in each axis to build the stage you need.