S35 LINEAR MODULES

When selecting a pre-assembled linear motion system, begin by evaluating the four core application parameters: stroke length, load capacity, travel speed, and positioning precision.

Once the magnitude and priority of these factors are defined, additional considerations such as noise levels, structural rigidity, and environmental conditions will help refine your options—streamlining the sizing and selection process.

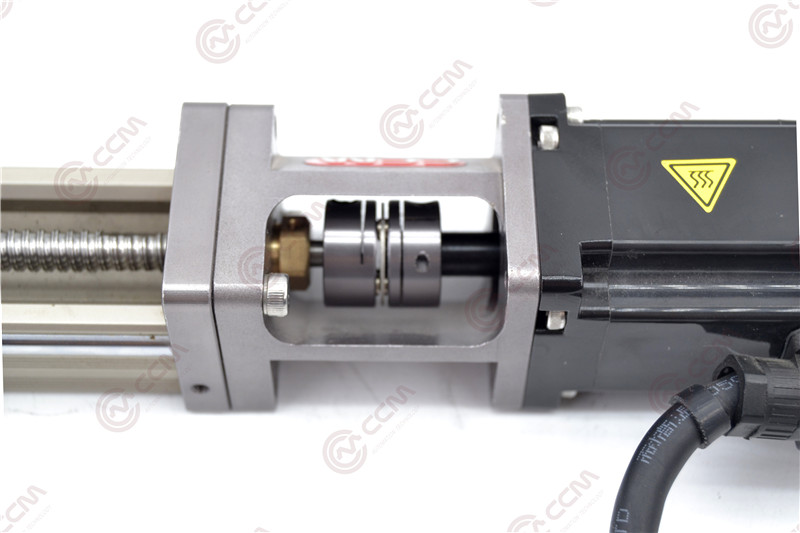

This specific model features a robust aluminum alloy and stainless steel construction, offering excellent durability and a self-cleaning design for reduced maintenance.

-

Load capacity: 5 kg to 15 kg

-

Positioning accuracy: ±0.02 mm

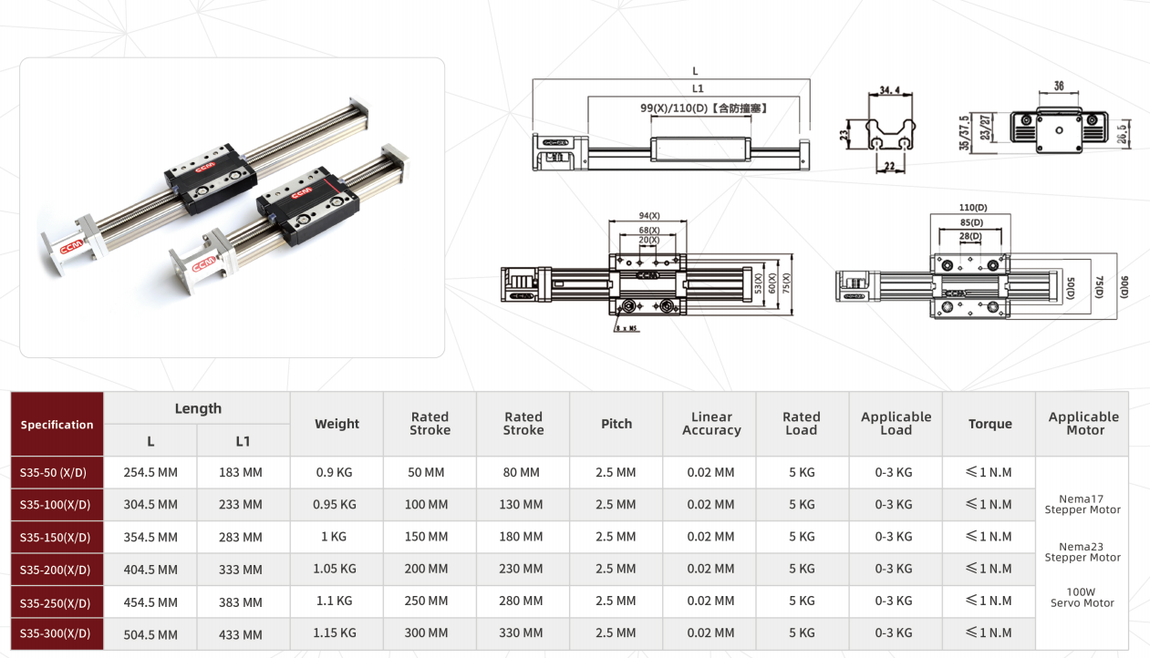

S35-50 LINEAR MODULE

- Positioning repeatability: <0.02MM

- Load capacity: 5KG

- Width: 35MM

- Pitch: 2.5MM

- Max length: 254.5MM

S35-100 LINEAR MODULE

- Positioning repeatability: <0.02MM

- Load capacity: 5KG

- Width: 35MM

- Pitch: 2.5MM

- Max length: 304.5MM

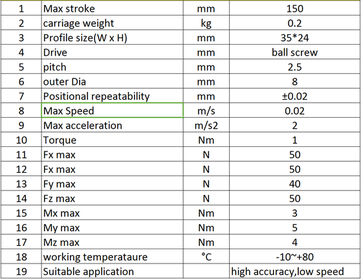

S35-150 LINEAR MODULE

- Positioning repeatability: <0.02MM

- Load capacity: 5KG

- Width: 35MM

- Pitch: 2.5MM

- Max length: 354.5MM

S35-200 LINEAR MODULE

- Positioning repeatability: <0.02MM

- Load capacity: 5KG

- Width: 35MM

- Pitch: 2.5MM

- Max length: 404.5MM

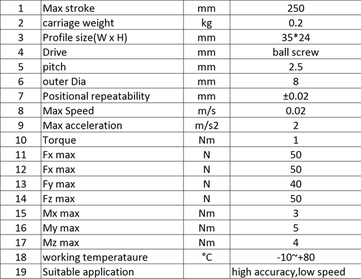

S35-250 LINEAR MODULE

- Positioning repeatability: <0.02MM

- Load capacity: 5KG

- Width: 35MM

- Pitch: 2.5MM

- Max length: 454.5MM

S35-300 LINEAR MODULE

- Positioning repeatability: <0.02MM

- Load capacity: 5KG

- Width: 35MM

- Pitch: 2.5MM

- Max length: 504.5MM

We offer motorized stages that can be assembled into many different configurations; for example, XY stages, XYZ stages . We list a few common XY stage combinations here, but you can select your own combination of family, travel and lead screw pitch in each axis to build the stage you need.